The growing demand for refrigeration and air conditioning equipment and the steady growth of the pharmaceutical industry drive the refrigerant market.

When we talk about refrigerants, we should also speak of their effect on the environment. After all, climate change has become the corporate responsibility of every business in the world. A refrigerant is a working fluid used in the refrigeration cycle of the cooling and heating systems. It undergoes a repeated phase transition from a liquid to a gas and back again and is heavily regulated due to its toxicity, flammability, and contribution to ozone depletion and climate change.

Refrigerants can be classified into fluorocarbons, hydrocarbons, and inorganic refrigerants. Among these, ammonia is the fastest-growing refrigerant due to its reduced environmental effects. The application of refrigerant can be found in domestic, industrial, and commercial air-conditioning systems, chillers, heat pumps, refrigeration systems, and mobile air-conditioning. Urbanisation and population increase the demand for air conditioning, while the ever-growing automotive and transportation industries increase the demand for portable air conditioning systems.

The refrigerant market ecosystem

The global refrigerant market is estimated to reach USD 8.4 billion by 2027 at a 6.2 percent CAGR from 2022. The growing demand for refrigeration and air conditioning equipment and the steady growth of the pharmaceutical industry drive the refrigerant market. Urbanisation and comfort lifestyle demands efficient air conditioning, which also contributes to the development of the refrigerant market.

Geographically, increasing population and industrialisation drive the domestic, commercial, and industrial air conditioning needs in Asia-Pacific, while the technological advancement and dependence on refrigeration in the food industry create a high demand for ammonia-based cooling and heating solutions in North America and Europe. Urbanisation and rapid industrialisation are vital in the Middle East and Africa. In South America, on the other hand, improving lifestyle and population creates a high demand for refrigerants.

In summary, the rise in demand for refrigerants from air conditioning is the key market driver, while the difficulties in transportation and storage play the role of the vital market restrainer.

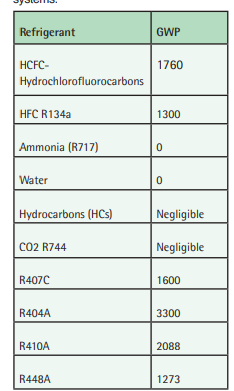

The many drawbacks of popular refrigerants When we talk about refrigerants, we should also talk about their effect on the environment. After all, climate change has become the corporate responsibility of every business in the world. In this view, we present the table below that depicts the ODP (Ozone Depleting Potential) value of the top ten refrigerants prevalent in the present cooling and heating systems.

There is a catch. Though most of the refrigerants listed above have zero ODP, they pose threats to the environment and workforce in one way or another. For example, ammonia causes toxic effects on humans, while HCs are highly flammable. Additionally, one must recognise the global warming potential (GWP) while choosing the company’s cooling and heating systems.

The suitable refrigerant for your business

Now you know ODP, GWP, and other inherent properties of popular refrigerants, you must wonder which refrigerant to use for your business. A refrigerant that is good for the environment and safe for your workforce to handle. The answer is simple. It’s the water.

What makes ‘water’ one of the best refrigerants?

- Zero ODP

- Zero GWP

- Non-toxic

- Non-hazardous

- Low cost

- Recyclable.

Though water sounds too simple for a refrigerant, it has the potential to generate cooling utilities as low as –5 deg C and heating utilities as high as 90 deg C using absorption technology. Whether it’s for a data centre, a large commercial complex or a crucial part of process cooling, water is the most eco-friendly and budget friendly refrigerant you can choose for your business.

Save the environment with Thermax. Apart from using a natural refrigerant (water), Thermax Vapour Absorption Machines (VAMs) recover and repurpose waste heat sources like steam, hot water, natural gas, thermic fluids, etc., to produce cooling and heating utilities for businesses. Since heat is the energy source, dependency on the electric grid to run the machine is greatly reduced, which gives a significant amount of energy and carbon savings. • Up to 80 percent energy savings

- Up to 90 percent carbon reduction

- Ozone-friendly refrigerant (water)

- Corrosion-free.

Case study for reference

A global automotive major collaborated with Thermax for an energy-efficient cooling and heating solution for its painting booth. As part of the automobile company’s efforts towards energy optimisation, Thermax has commissioned two cooling and heating solutions for its plant in Karnataka.

Targeting paint booths to reduce energy The paint booth is a significant component of automobile manufacturing. To deliver smoother finish and better user comfort, industries invest inefficient heating and cooling solutions for paint booths. The automobile plant in Karnataka was utilising steam from a propane-driven boiler to generate hot water, which in turn was used in the heating application for paint booths. Given the rising energy prices, the company aimed to reduce the energy (fuel and electricity) consumption in the paint booth. Hence, the company approached an operational excellence and energy conservation consultant to replace the existing electric solution with an alternative heating solution that could relieve the boiler’s load.

Partnering with Thermax for a comprehensive solution

Thermax, an absorption technology leader with a history of delivering guaranteed results across industries, led the energy conservation consultant to partner with Thermax for the heating solution. Upon detailed analysis of the available utilities and requirements, it was found that the plant, in addition to the hot water, required chilled water but without a cooling tower. Hence, experts from Thermax positioned the Heat pump chiller as the perfect fit for the plant.

Meeting two demands with one solution.

Two direct-fired absorption heat pump chillers were commissioned at the automobile plant. The machines of capacity 560KW/36TR and 1050kW/69TR run on propane and deliver hot water at 90°C and chilled water at 7°C. The machines simultaneously cater to processes such as paint shop primary heating and secondary cooling while offering comfortable cooling in AHU (Air Handling Unit).

By doubling up as heating and cooling solutions, the heat pump chillers offer numerous energy and economic benefits to the automobile company

- Grid Independence

- Minimised electricity consumption

- Decrease in operational expenditure

- Reduced load for steam boiler

- 20 percent fuel savings Much more than energy optimisation

- Enhanced reliability

- Low maintenance

- Reduced CO2 footprint.

The transition to absorption cooling and heating systems using water as the refrigerant presents various environmental and economic advantages. Water is natural and poses no threat to your workforce and environment. In addition, waste heat recovery and absorption technology based cooling and heating solutions from Thermax are good for business and the environment.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.