As the world grapples with the imperative to reduce greenhouse gas emissions, the adoption of eco-friendly refrigerants emerges as a viable solution to combat escalating global temperatures. However, Ammonia refrigeration ekes out due to its natural properties, promoting energy efficiency and offering cost-effective cooling solutions, particularly within the pharmaceutical industry.

The objective of choosing artificial refrigerants with low Global Warming Potential (GWP) is to mitigate the release of greenhouse gases, thereby addressing the challenge of reducing global temperatures. This has become a global focal point in the refrigeration and air conditioning industry, with developed nations like Europe and the United States advocating for Hydrofluoroolefin (HFO) and natural-based refrigerants. While conventional refrigerants like R134a, R410A, and R404A are prevalent in the Indian market due to their lower costs, there is a growing interest in natural hydrocarbon refrigerants as they offer a direct approach to combating global warming. Various alternative technologies utilising low-GWP refrigerants such as Hydrocarbon, Ammonia, CO2, and others are available, providing cost-effective solutions while reducing emissions.

Dr. Vijai Singhal, Director of GreenHub Systems, notes that the shift towards alternative technologies is primarily motivated by equipment’s improved energy efficiency, which creates significant business prospects. This transition can positively alter the market dynamics, even without a global agreement to regulate emissions of Hydrofluorocarbons (HFCs). Consequently, there is an increasing need within the Indian Refrigeration and Air Conditioning sector for easily accessible information to assist companies in adopting environmentally friendly refrigerants and related technologies.

Global shift towards eco-friendly refrigerants

The refrigeration technology market is witnessing massive growth, with companies increasingly focusing on advanced cooling technologies, especially natural refrigerants. This strategic shift signifies a direct transition towards energy-efficient and eco-friendly refrigerants.

Multinational corporations actively compete for market leadership in room air conditioners, domestic refrigerators, and commercial cooling equipment sectors. They are now manufacturing products that meet stringent government regulations while achieving economies of scale. Compliance with these regulations facilitates the unrestricted global marketing of their products. Globally, many countries are embracing refrigerants with reduced climate impact.

What was once seen as a hindrance to adopting natural refrigerants has transformed into a strategic business opportunity. This approach improves the efficiency of refrigeration systems and lowers operational costs, thereby positively impacting climate change. The current advancements aim to enhance the utilisation of ammonia in various industries, focusing on optimising energy efficiency and safety measures within the ammonia refrigeration sector through innovative technologies.

Ammonia refrigeration

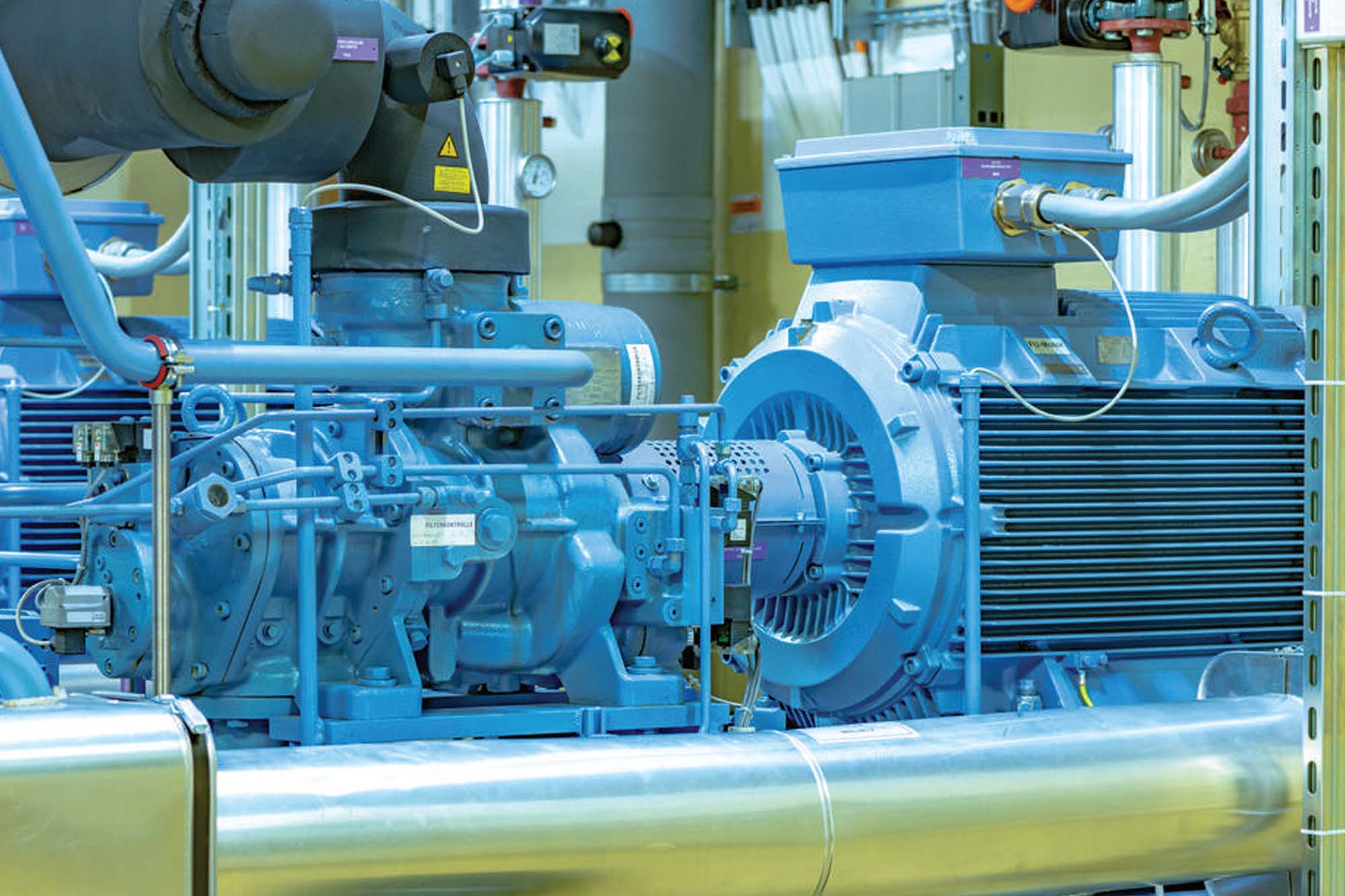

Ammonia acts as a natural refrigerant, carrying almost zero environmental impact. Moreover, it undergoes rapid decomposition into nitrogen and hydrogen when released into the atmosphere, resulting in minimum environmental harm. Anand Joshi, General Manager of Manik Engineers, emphasised India’s achievement of complete self-sufficiency in ammonia refrigeration systems. All necessary components and equipment for constructing these systems are domestically manufactured, aligning with the principles of self-reliant India. This development showcases technological advancement reaching the country’s urban and rural areas. The Ammonia Refrigeration Association (AAR) has organised over 100 technical training programs, disseminating knowledge to ammonia refrigeration engineers, technicians, and plant operators.

Ammonia in pharma and F&B industry

Ammonia is a natural refrigerant widely used in large-scale refrigeration systems in sectors like food and beverage manufacturing and cold storage warehouses. According to Navneet Rohilla, Associate Tech Lead at Trane Technologies, ammonia refrigeration systems enable temperatures as low as -60°C while consuming significantly less power than other refrigerant-based systems.

Agus Maulana, Project Engineer at PT Aswifa Maju Jaya Bersama, highlights that NH3 refrigerant possesses high toxicity, necessitating the implementation of safety measures in case of a cooling system leak. However, NH3 refrigerant offers an environmental advantage as it does not contribute to carbon footprints in the atmosphere in the event of a leakage. Moreover, NH3 refrigerants can efficiently generate and maintain precise temperatures.

On the other hand, carbon dioxide has gained popularity for freezer applications due to its effectiveness at low temperatures. Unlike ammonia, CO2 does not pose the same risks of toxicity and explosion in the event of undetected gas leaks exceeding safe concentration levels or exposure durations. To mitigate risks associated with ammonia, leak detection systems are often installed to enhance safety measures.

Ammonia has the highest latent heat among refrigerants, about 5 to 6 times greater than synthetic ones, making it highly efficient. It is also cost-effective and environmentally friendly, with zero impact on climate and a high Ozone Depletion Potential. Its versatility across a wide temperature range, from +10°C to -50°C, makes it ideal for pharmaceutical cooling, ensuring rapid and energy-efficient temperature adjustments.

However, its toxicity risks the food and beverage sector, especially in areas with frequent public access. For safety reasons, Raman Singh, Lead System Engineer and HVAC-Alstom. advises against using it in supermarkets, modular cold rooms, deep freezers, and bottle coolers. Instead, he recommends restricting its use to locations with limited access to minimise exposure.

Navneet suggests that due to its high latent heat, ammonia is more suitable for large cold rooms rather than small appliances like bottle coolers. Dr. Vijai agrees, highlighting the pharmaceutical industry’s reliance on refrigeration for drug preservation. In this sector, ammonia, CO2, or HFC/HFO compounds with ammonia as the main refrigerant are commonly used due to their efficiency and lower system costs than HFC-based systems. However, caution is necessary due to ammonia’s toxicity to humans, especially in large amounts.

According to Anand, implementing ammonia refrigeration systems in the Food & Beverage sector presents challenges. The main challenge revolves around the necessity for increased marketing initiatives and funding dedicated to advocating for ammonia as the most environmentally friendly and energy-efficient refrigerant. Companies dealing with synthetic refrigerants typically possess larger financial resources, allowing them to mislead end-users easily. As a result, the ammonia refrigeration industry must address financial discrepancies and counteract the influence of well-funded lobbying campaigns by manufacturers of synthetic refrigerants.

Safety and advantages of using ammonia

It is imperative to adhere to safety measures when working with ammonia refrigeration systems, especially in areas where food processing or pharmaceuticals are involved. Ensuring a safe working environment in such plants requires strict compliance with standard safety guidelines. Addressing concerns regarding flammability and toxicity is important for the widespread use of these substances, taking into account product economics. Safety issues, particularly those related to flammable refrigerants, are a major concern for end-users. Educating end-users about the chemical properties of alternative options and providing adequate training for handling flammable refrigerants are essential steps.

Following established protocols outlined by the Association of Ammonia Refrigeration and other relevant standards can ensure the safe operation of ammonia plants over extended periods. A commitment to safety measures in ammonia refrigeration systems is vital for safeguarding personnel and the sensitive processes involved in food and pharmaceutical production.

The Association of Ammonia Refrigeration has issued the AAR-01 standard for ammonia refrigeration plant design. The Bureau of Indian Standards has adopted it, and it is available as the National Standard. While currently optional in India, making such standards mandatory would enhance ammonia refrigeration plants’ overall performance and safety.

Ammonia is a highly efficient and economical heat transfer fluid compared to HFCs or HFOs. Presently, various regulations are in place to ensure safe operations. Raman stresses the importance of regulatory bodies like the AAR publishing guidelines to guarantee operational safety. Governments must ensure the implementation of proper safety protocols to uphold the standards of ammonia usage.

However, consumer acceptance of environmentally friendly technologies in developing countries still needs to be improved due to safety concerns and higher costs than conventional HFC-based technologies.

Natural refrigeration technologies offer benefits and can be integrated into corporate social responsibility (CSR) initiatives. Manufacturers are willing to provide technologies based on various refrigerants according to consumer demand. However, addressing safety and cost concerns is essential for a successful transition in the country.

The global trend reflects a collective commitment to exploring low global GWP alternatives and reducing greenhouse gas emissions. India’s Cooling Action Plan (ICAP) aligns with this goal despite a push for a faster approach. Due to global initiatives to phase out and reduce HCFCs and HFCs, ammonia is increasingly seen as the most suitable refrigerant for cold storage in the pharmaceutical industry.

There is expected to be a growing application of ammonia in the future, particularly due to its high efficiency. However, its suitability lies more with large systems than small freezers used in medical stores or labs. Ammonia can be utilised effectively in warehouses or during the transportation of vaccines. In summary, ammonia refrigeration holds great promise for the pharmaceutical industry, especially for temperature-sensitive materials, due to its natural refrigerant status.

=======

Navneet Rohilla, Associate tech lead -Residential AC USA market, Trane Technologies.

Ammonia is suitable for large systems but not for small Freezers; hence, it can be used in warehouses or during the transportation of vaccines.

Raman Singh, Lead System Engineer- HVAC, Alstom.

Regulatory bodies such as the AAR should publish guidelines to ensure the safety of operations, and the government must also ensure proper safety protocols are in place.

Anand Joshi, General Manager, Manik Engineers.

Ammonia emerges as the most favourable refrigerant, facilitating rapid and energy-efficient temperature changes in the cooling of sensitive pharmaceutical materials.

Agus Maulana, Project Engineer, PT Aswifa Maju Jaya Bersama (AMJB).

NH3 refrigerant material offers an environmental advantage, as it does not contribute to carbon footprints in the atmosphere if it leaks.

Dr. Vijai Singhal, Director, GreenHub Systems Private Limited.

Consumer acceptance of environment-friendly technologies in developing countries needs to be more adequate due to safety concerns and higher costs compared to conventional HFC-based technologies.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.