CSW motor version 4 enables OEM screw chiller manufacturers to design and produce water cooled AC chillers that fulfil the highest international energy efficiency standards.

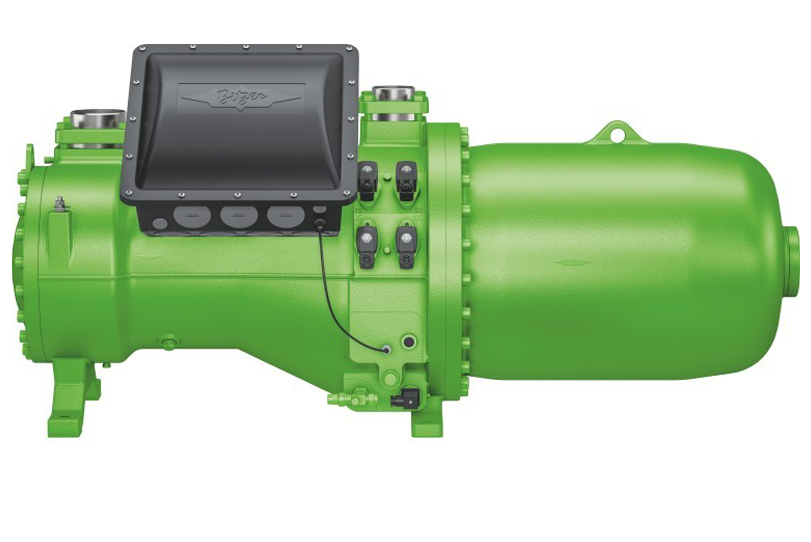

BITZER presents its new compact screw compressor CSW85/95 motor version 4 for improved efficiency in water-cooled high-performance liquid chillers. The new compressor motor selection allows manufacturers to achieve the latest efficiency requirements.

CSW motor version 4 is a combination of the BITZER CSW screw compressor with a special selected motor version 4 and special oil charge. Due to increasing efficiency requirements and corresponding customer demand, especially from Europe and India, BITZER now started manufacture of its CSW for the corresponding markets ex works the BITZER Rottenburg-Ergenzingen site.

The number of water-cooled systems is notably increasing in Europe – also due to the requirements of the Ecodesign Directive. CSW enables OEM screw chiller manufacturers to design and produce water-cooled air conditioning chillers that fulfil the highest international energy efficiency standards like the European Eco-design 2016/2281 tier 2 and the Indian BEE-ECBC – ISEER star rating.

New possibilities for chiller manufacturers

The product range covers nine models with displacements between 410 m³/h and 1,120 m³/h at 50 Hz as well as 495 m³/h and 1,351 m³/h at 60 Hz. Their application envelope was designed for highly efficient water-cooled air conditioning and process chiller applications with maximum condensing temperatures up to 46°C, which is why their technical concept includes various measures to improve the compressor’s efficiency: the motor features increased efficiency in the target application envelope and a reduced maximum operating current. This gives the possibility to use smaller contactors and smaller mains cable diameters, resulting in an overall system cost reduction. CSW was designed for low-pressure medium and low GWP refrigerants like R134a, R1234yf, R513A, R450A, R1234zeE and R515B.

The combination CSW with motor version 4 and the optimised oil version allows for efficiency to meet the specifications. The mechanical capacity control with single slider concept can be adjusted between 100 and 25 percent. This CSW version is also suitable for operation with an external frequency inverter at a frequency range between 20 and 60 Hz.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.