Maintaining good indoor air quality at hospitals has become a challenging task. Here’s an in-depth analysis on how the concept of air handling is changing post-COVID-19.

Importance of air handling in healthcare industry

Air handling in healthcare industry is much critical and trickier than any other commercial applications. Maintaining adequate filtration which can handle viruses and bacteria (HEPA filters), using cleaning technologies like UV, pressurisation requirements in various areas, ventilation and RH requirements are typical of this application.

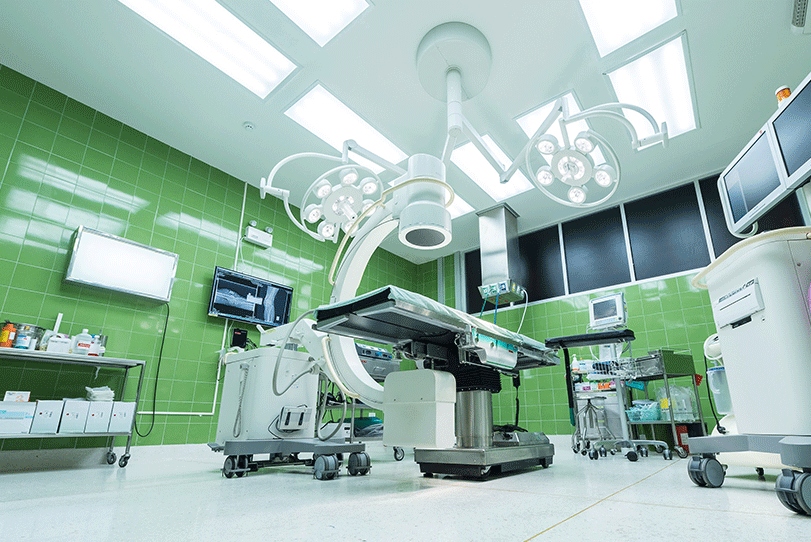

Healthcare sector requires more than just microbiological monitoring. Proper attention should be given to air conditioning, ventilation and filtration systems so as to keep the environment inside clean and safe for the patients. The role of air handing is very important and challenging in ultra clean OTs used for procedures in the areas of neurosurgery, organ transplant etc, where bacterial contamination is more critical.

DRI has always understood the importance of air handling in the OT (operation theatre) or healthcare industry, said Rahul Aeron, Assistant VP, Sales, DRI – Pahwa Group. “OT is such a place where even though a patient may spend only a brief time for a procedure, it’s environment plays a great role in the onset and spread of infections. These infections can be caused due to various things acting as contaminants – the biggest possible contaminant is the air around us, and rest being equipment, infected body fluid, indoor environment etc.”

He adds, “Good Indoor Air Quality (IAQ) depends on adequate supply of fresh air, absence of pollutants and good distribution of air to the breathing zone. It is established that a properly equipped and maintained HVAC system is mandatory for healthcare facilities to use less energy and be less costly to maintain.”

Best strategy to improve IAQ in healthcare facility

IAQ in healthcare facility is more critical as the patients have less immunity. Explaining the best strategy to improve IAQ in healthcare facility, Neeraj Gupta, Senior General Manager – Living Environment Division, Mitsubishi Electric India said, “The best strategy to improve the air quality is to invest in proper forced air ventilation system that can bring the fresh air to replace polluted air.”

Mitsubishi Electric air conditioners offer advanced ventilation systems that can create sustainable and healthy environment for occupants. To safeguard people from extreme temperature and pollution and to enhance the IAQ, the company provides Lossnay Ventilation System. Lossnay systems were developed and refined over the past 35 years, the Lossnay have perfected mechanical ventilation with recovery of heat energy that would otherwise have been wasted. This helps to reduce overall energy cost by extracting stale air and then recovering the heating or cooling energy to either warm or cold incoming fresh air thereby minimising energy loss, maximum heat recovery leading to substantial energy savings, claims Gupta. He said, “City Multi VRF system along with Lossnay ventilation system works as perfect combination for healthcare facilities.”

How the concept of air handling is changing post-COVID-19

Ventilation is becoming the key as countries across the world learn to work alongside COVID-19 and prepare for a post-COVID world. So the demand for technologies and products enabling ventilation is increasing. The HVAC industry is likely to see many changes as a result, which would make them look at things from a new perspective and expand in this industry. For example, there will be rising demand for products energy recovery ventilators, air purification systems which can increase the ventilation, while saving energy and can be retrofitted.

Commenting on how the concept of air handling is changing post-COVID-19, Aeron said, “There is likely to be more of a focus on development and use of more environmentally friendly products in air handling, as people begin to realise the utmost importance of sustainability and the need to move towards greener products. Technology will also be playing a major role in the future of the industry, especially as prudent ventilation in air conditioned spaces and use of evaporative cooling in industrial spaces can help in ensuring clean fresh air free of contaminants, with health of employees becoming a top priority.”

According to Gupta, “The concept of IAQ has become important and changed perception of people in post COVID-19 scenario. Earlier the term maintaining IAQ for most of the customers was limited only upto air conditioner filter cleaning but now, we need advanced measures to remove stagnant polluted air and bring clean fresh air in to the room.”

Ventilation of conditioned spaces to dilute the indoor air pollutants in the space is becoming saviour during this pandemic. Many international papers are now recommending increasing ventilation in occupied spaces and even suggesting 100 percent outdoor air systems. This increased amount of ventilation should definitely solved IAQ related problems, said Aeron. However, he observed, the inability to maintain the right humidity by our HVAC systems may lead us to other problems. Mold and mildew are serious dilemmas which are caused by lack of humidity control. Also the growth of viruses and bacteria can augment if proper humidity is not maintained in the conditioned spaces. The question is: Have we traded one problem with the other?

DRI’s DOAS provide safe environment in OT

Keeping in mind the problems faced in the healthcare industry, DRI’s special healthcare DOAS (Dedicated Outdoor Air Systems) provide a guaranteed safe environment in the OT, asserts Aeron. “It matches up to the NABH guidelines and provides a clean and safe environment. Our AHUs also ensure the right air quality as per international standards. They recover energy from the exhaust air, resulting in considerable reduction in installed tonnage and utility bills. They also help in enhancing the IAQ, maintain the desired temperature and humidity and hence helps in increasing productivity.”

All these functions are available with the help of: Temperature control, humidity control, VFD (for constant air volume), weekly schedule/night mode, variable frequency of the fan, and control panel etc. on the board/remote.

DRI also has Treated Fresh Air (TFA) units with EcoFresh wheels inside that provide the required fresh air with the low running costs. It is designed and manufactured using a selection of materials to comply with hygiene needs. It exhausts stale, contaminated conditioned room air and exchanges it with fresh outside air, recovering upto 75 percent energy from the exhaust air through a next generation EcoFresh rotor.

“Post COVID-19, the entire focus is on ventilating conditioned spaces and DRI has always been on forefront in ventilation technologies or applications. Hence, we actually were ahead of times and didn’t have to do much to introduce new products. However, slight tweaking have been done to meet the huge retrofit demand by providing more and more of packaged systems like DOAS and TFAs with integrated refrigeration systems and controls packages,” Aeron said.

He adds, “Our ERVs (energy recover ventilators) are ideal for retrofitting in office spaces while are evaporative coolers provide cooling and ventilation in large spaces like shop floors. Our air purification system is another product which is ideal for air-conditioned classrooms and offices.”

MEI’s focus on maintaining IAQ

The environmental problems are still affecting the human health and deteriorating the air we breathe. The technology behind the energy efficiency of Lossnay lies in the construction of the core which enables the exchanges of both latent heat (humidity or moisture) and sensible heat (temperature) to maintain a comfortable internal environment for minimal energy consumption and without cross-contamination.

Answering to a query on Mitsubishi Electric’s introduction of IAQ-related product post-COVID-19, Gupta reveals: “Although, we already have products to maintain IAQ, but specific technology for protection from COVID-19 not yet commercialised. We are currently emphasising on the measures to maintain the IAQ to minimise the impact of spreading of COVID-19 in air-conditioned areas.”

He adds, “Novel coronavirus containment and eradication methods are not yet commercialised. We can’t put a timeline on the commercialisation of the various technologies tested by our factories. Let us all hope for a faster introduction of the products in India.”

The best strategy to improve the air quality is to invest in proper forced air ventilation system that can bring the fresh air to replace polluted air.

Neeraj Gupta, Sr. GM – Living Environment Division, Mitsubishi Electric India

It is established that a properly equipped and maintained HVAC system is mandatory for healthcare facilities to use less energy and be less costly to maintain.

Rahul Aeron, Assistant VP, Sales, DRI – Pahwa Group

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.