This article explains what a heat exchanger is and why it is critical for the functioning of the commercial buildings

The need to either take out heat from a space or add heat to a space has been a human need for times immemorial. Eskimo’s made Igloos to retain heat inside their dwellings in the freezing arctic cold while the “Jharokas” in Rajasthan helped keep the rooms cool in peak summers. Before the advent of air conditioning, natural means were used to obtain the desired temperature in homes, offices, schools etc. These systems were dependent on the ambient conditions and there was limited control that the people using these systems had, except maybe to turn off the whole system! As populations grew and the number of people using a space increased, and habitation moved away from the rural to the urban, the natural way of conditioning of spaces was not enough. Mechanical ventilation and subsequently the technique to artificially cool the air were developed as an outcome of the need to provide a good work and living environment for the occupants.

The major difference between natural and mechanical air conditioning is that in the later, air from the workspace which has got heated up due to transfer of heat from the occupants has to be cooled and then resent into the workspace. This cycle repeats to provide the occupants the desired temperature and the place where the exchange of heat from the warm air takes place is called the Heat Exchanger (HE). In this case, heat exchange occurs between a cooling medium ( a refrigerant gas in the air handling unit of a room) and the air but heat exchangers are used in various applications where there is a need to transfer heat from one place to the other. A simple desert cooler is an example of a HE – warm air from outside is drawn across the cooling pads where the water absorbs the heat in the air and the cool air is thrown into the room. In this case, the heat exchanger is the straw pads of the cooler.

HEs in Commercial Buildings

A building has many systems running round the clock to provide the occupants the required level of comfort to enable them to work productively. The air conditioning system is the one that most people associate with comfort as they experience it. However, there are other systems too that are essential for the operations of the building. The Diesel Generators provide backup electricity to the electrical system and hence are crucial from a business continuity point of view. Domestic water systems in many buildings provide clean drinking water through distributed cooling stations. These are some examples of building systems that are needed to provide a comfortable work environment, and all these have HEs. Table 1 lists the HE that are found in a typical commercial high-rise building that uses centralised air conditioning systems.

| Building System | Heat Exchanger | Heat Exchange Medium |

| Air conditioning | Condenser | Gas/Liquid |

| Evaporator | Liquid/Liquid | |

| Cooling Tower | Liquid/Air | |

| AHU | Liquid/Air | |

| Diesel Generator | Radiator | Liquid/Liquid |

| Cooling Tower | Liquid/Air | |

| Drinking water system | Water Coolers | Liquid/Gas |

Why HEs need special attention?

The heat exchange process is a complex one – there are many factors that affect the transfer of heat from one medium to the others. These include the nature of the material, the surface area that is being exposed to the medium, the velocity of the medium flowing across the surface, the heat absorption capacity of the mediums and any others. The science of HEs has evolved considerably over the last 200 years and the modern HE is a state-of-the-art, highly efficient device that is critical for the functioning of the equipment or system that it is used in. Figure 1 shows the various factors that come into play during transfer of heat.

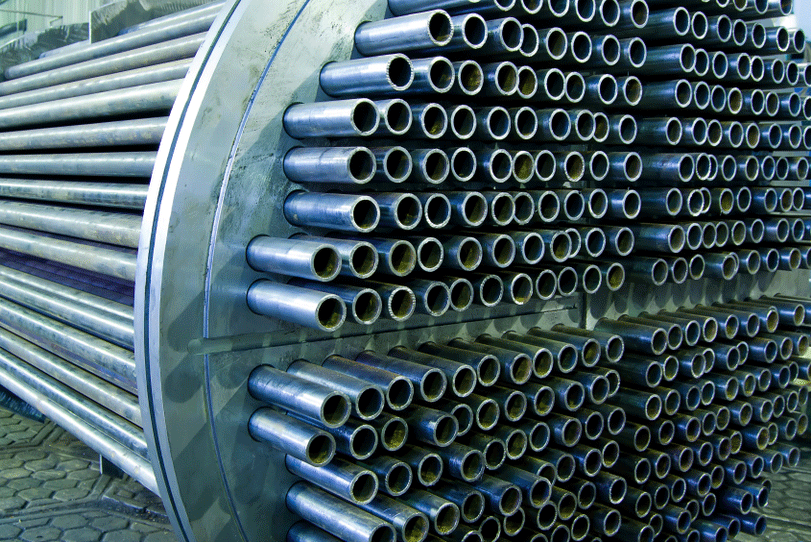

Like any multi-variable system, a change in one of the parameters that impacts heat transfer will impact the overall rate of heat transfer. If the flow rate reduces, the heat taken away by the medium will be less and there will be an overall impact on the system efficiency. The most used HEs in commercial building applications are the shell and tube type ones, where one medium is circulated in multiple passes of tubes in a shell that has the other medium flowing through it. These are usually cross flow type HEs to allow for maximum velocity of the fluids for maximum heat transfer. The condensers and Evaporators are of this type. The HE used in diesel gen sets have either a fan blowing air over the radiator fins around the tubes in which the water or in the case of water-cooled engine systems, the cooling tower is used to cool the engine water.

Any deterioration of the heat exchange surfaces will reduce the amount of heat transferred resulting in the system not functioning as per design. For example, in a central air conditioning plant, if the condenser cooling surfaces have degraded, then the condensation of the refrigerant will get impacted, leading to higher system pressures and lower cooling. A one degree increase in evaporator chilled water supply temperature by better heat exchange will reduce energy use by 2 percent. Similarly, if the HE of a DG set is not functioning properly, the cooling water temperature will increase and cause the engine to overheat and ultimately, reduce the units produced per litre of diesel.

Causes of Poor HE performance and Remedies

During the course of a HE’s operating life, like any other equipment or system, there are degradations in the equipment, changes in the operating parameters, mechanical failures etc. that ultimately cause the HE to operate at an off design point and in turn effect the operation of the overall system. A HE’s performance is measured by the amount of heat that can be transferred on in layman terms, the amount by which the temperature can be brought down or up of the cooled medium. Some of the causes that impact the performance of a HE in a commercial building environment are

• Poor quality of water: When the water in the chilled water system or condenser system is not maintained to the desired parameters ( Ph, TDS, microbiological content etc.), the heat exchange surfaces get effected as a layer of contaminants get deposited which reduces the heat transfer capacity. This is commonly called scale formation and can cause heat transfer efficiency to come down by 25 – 30 percent in extreme cases.

• Mechanical damage: When the cooling medium has solid impurities or rust formation occurs within the pipes, pitting occurs which results in increased resistance to flow, which in turn leads to lower heat transfer and higher pumping energy

• Blocked tubes: This is a common phenomenon in air conditioning system HEs where due to the continuous use and lack of regular maintenance, tubes get punctured and are blocked to prevent mixing of the cooling mediums. If the number of tubes that are blocked increase beyond the limit advised by the OEM, the flow rate will reduce and the HE efficiency will get impacted.

• Inadequate flow rates: When a system design is changed during the life of the equipment (due to operational reasons) and the HE is not redesigned of modified for the new operating conditions, the flow rates will change leading to inadequate heat exchange and system performance. A good example is the change of seating arrangements in a workspace and the AHU and ducting system not being re assessed, leading to hot spots in the workspace.

• Dust accumulation: This factor comes into play in HE’s where air/liquid heat transfer occurs. Dust on the fins of the HE can cause a significant reduction in the heat exchange rate leading to degradation of the system performance.

Keeping the HE Happy and Efficient

HEs are be design very simple and robust devices and can perform well for long periods of time. However, they are also very sensitive to changes in design parameters and hence simple maintenance practices will ensure that the HE functions the way it should. Some of the simple but effective maintenance practices that O&M team can undertake are:

• Water quality: This is the one area that most maintenance teams miss and the area that is the easiest to have control of. Timely testing of the water quality to see that the parameters recommended by the manufacturer are met is of utmost importance. In addition, maintaining water system hygiene will also prevent contamination of the cooling medium and prolong the life of the HE.

• Heat transfer surface cleaning: Despite maintaining water hygiene and water quality, there will be some amount of scale formation or deterioration of the heat transfer surfaces over a period. It is thus essential that the tubes and fins are cleaned at regular intervals as per OEM recommendations. An auto tube cleaning system (ATCS) for condensers of chiller plants is a good addition as it can reduce the approach temperature by 2- 3 degrees leading to significant energy savings.

• Operating at correct design parameters: The operations team should regularly check the operating parameters of the HE such as water temperature, flow rates, pressure etc. so that the HE operates at the design point and there is no scaling or fouling of the tubes. An important aspect is to regularly undertake trend analysis of system parameters to see that the HE is working at the desired efficiency.

Conclusion

HEs have evolved considerably over the last 40 – 50 years, with increasing heat transfer efficiency and ability to operate across larger ranges of temperatures at high efficiency. This has been possible due to advances in metallurgy, system design and manufacturing processes. However, the flip side of these improvements is that the HE is now more sensitive to changes in operating parameters such as surface heat transfer coefficient and flow rates. The margin of error has reduced and hence, the O&M team must keep the HEs in a very high level of operational efficiency through good maintenance practices. This will not only enhance the life of the HE but also lower operating costs and reduce break downs.

(Views shared are personal in nature)

Authored by

Aneesh Kadyan, Executive Director–Property Management,

CBRE South Asia Pvt Ltd

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.