The startup Transaera is using a class of materials, for over a decade, to create a more energy- efficient air conditioner.

The demand for air conditioners is expected to triple by 2050. As the progressing and changing revenues in developing countries continue to rise, the surge will further multiply to what is already a major source of greenhouse gas emissions. Air conditioning is currently responsible for almost 20 percent of electricity use in buildings around the world. Now a startup, Transaera, is working to curb those energy demands with a more efficient air conditioner that uses safer refrigerants to cool homes. The company believes its machine could have one-fifth the climate impact of traditional ACs.

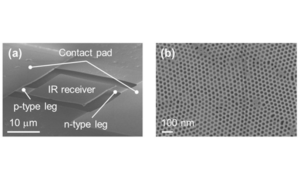

“The thing about air conditioning is the basic technology hasn’t changed much since it was invented 100 years ago,” says Transaera Chief Engineer Ross Bonner SM ’20. That will change if Transaera’s small team is successful. The company is currently a finalist in a global competition to redesign the air conditioner. The winner of the competition, named the Global Cooling Prize, will get $1 million to commercialise their machines. At the heart of Transaera’s design is a class of highly porous materials called metal organic frameworks, or MOFs, that passively pull moisture from the air as the machine works.

Co-founder Mircea Dincã, the W.M. Keck Professor of Energy in MIT’s Department of Chemistry, has done pioneering research on MOFs, and the company’s team members see the materials’ commercial advancement as an important part of their mission. “MOFs have a lot of potential applications, but the thing that’s held them back is unit economics and the inability to make them in a cost-effective way at scale,” says Bonner. “What Transaera aims to do is be the first to commercialize MOFs at scale and lead the breakthrough that brings MOFs into the public domain.”

Dincã’s co-founders are Transaera CEO Sorin Grama SM ’07, who is also a lecturer at MIT D-Lab, and CTO Matt Dorson, a mechanical engineer who worked with Grama on a previous startup. “I’m just incentivized by this idea of creating something revolutionary,” says Grama. “We’ve designed these new devices, but we’re also bringing this material knowledge, with Mircea and our collaborators, and blending the two to create something really new and different.”

A material of opportunity Grama and Dorson previously collaborated at Promethean Power Systems, which develops off-grid refrigeration solutions for farmers in India. To date, the company has installed 1,800 refrigeration systems that serve roughly 60,000 farmers each day. After stepping down as CEO in 2015, Grama returned to the Institute to teach at MIT D-Lab and serve as an entrepreneur-in- residence at the Martin Trust Center for MIT Entrepreneurship. During that time Grama was introduced to MOFs by Rob Stoner, the MIT Energy Initiative’s deputy director for science and technology and a founding director of the MIT Tata Center.

Stoner introduced Grama to Dincã, who had been studying MOFs since he joined MIT’s faculty in 2010 and grew up 10 miles from Grama’s hometown in Romania. MOF’s intriguing properties come from their large internal surface area and the ability to finely tune the size of the tiny chambers that run through them. Dincã previously developed MOFs with chambers just big enough to trap water molecules from the air. He described them as “sponges on steroids.” Grama began thinking about using the material for refrigeration, but another application soon presented itself.

Most people think air conditioners only cool the air in a space, but they also dry the air they’re cooling. Traditional machines use something called an evaporator, a cold coil to pull water out of the air through condensation. The cold coil must be made much colder than the desired temperature in the room in order to collect moisture. Dorson says pulling moisture out of the air takes up about half of the electricity used by traditional air conditioners. Transaera’s MOFs passively collect moisture as air enters the system. The machine’s waste heat is then used to dry the MOF material for continuous reuse.

Transaera was formally founded in the beginning of 2018, and the Global Cooling Prize was announced later that year. Hundreds of teams expressed interest, and Transaera was ultimately selected as one of eight finalists and given $200,000 to deliver prototypes to competition organizers. Bonner joined the company in 2019 after exploring paths to carbon neutral ACs as part of a mechanical engineering class at MIT. When Covid-19 began sweeping through countries around the world, it was decided the Cooling Prize’s trials in India would be run remotely. Adding to the challenge, the co-founders didn’t have access to their lab in Somerville due to restrictions and were using their own tools and garages to complete the prototypes.

After shipping off their prototypes, Transaera had to help Prize organisers install them through a live video feed for field trials. The team says the results validated Transaera’s approach and showed the system had a significantly lower climate impact than baseline units. Transaera’s system also used a refrigerant known as R-32 with zero ozone depleting potential (ODP) and a global warming potential about three times lower than another commonly used refrigerant. The milestone further convinced Transaera’s small team they were onto something. “This air conditioning problem can have a real, material impact on people’s quality of life,” Dorson says.

Pushing a field forward The Global Cooling Prize will announce its winner next month. Regardless of what happens, Transaera will be growing the team this year and running additional trials in Boston. The company has been working with large manufacturers that have supplied equipment for prototypes and shown the founders how they might integrate their devices with existing technologies. The company’s foundational work with MOFs has continued even as Transaera’s air conditioner gets closer to commercialisation. In fact, Transaera recently received a grant from the National Science Foundation to explore more efficient paths to MOF production with a lab at MIT.

“MOFs open up so many possibilities for all kinds of revolutionary devices, not just in air conditioning, but in water harvesting, energy storage, and super capacitors,” Grama says. “This knowledge we’re developing can apply to so many other applications down the road, and I feel like we’re pioneering this field and pushing the edge of the technology.” Still, Transaera’s founders remain focused on bringing their AC to market first, acknowledging the problem they’re trying to tackle is big enough to keep them busy for a while. “It’s clear when you look at the swath of the world that’s in the hot, humid tropics, there’s a growing middle class, and one of the first thing they’ll want to buy is an air conditioner,” Dorson says. “Developing more efficient air conditioning systems is critical for the health of people and of our planet’s environment.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.