With the update of the European Standard for powered smoke and heat control fans in 2015, options were provided to use smoke exhaust fans with variable speed drives (VSD) in case of a fire. This opened up new possibilities for safer, greener and more economical solutions.

Increasing the safety of a high-rise building, a car park or tunnel and at the same time reducing the running costs with more energy-efficient operation would be an exciting route to explore for many. With the changes in 2015 to the EN 12101-3 standard for powered smoke and heat control fans, this became a scenario within reach. The standard lays out three options:

1. Run the smoke fan at nominal motor speed without VSD. For this, you only need a certified smoke fan. You can use a VSD, but this VSD must be bypassed in case of a fire. This means you can only run the smoke exhaust at the nominal motor speed, which limits the flexibility for smoke operation significantly. Furthermore, the bypass option requires additional (costly) control equipment within the control panel.

2. Use a smoke fan with VSD, which have not been tested and certified as a package. With this set-up, you have to de-rate the motor power by 20 percent. Furthermore, you need an additional waveform filter between the frequency converter and the motor, which adds considerably to the costs. The costs will further increase since the VSD, emergency power supply and cabling also have to be designed for the 20 percent extra power reserve.

3. Use a certified smoke fan with VSD package, where the complete package is tested and certified for smoke and heat control systems. This solution enables you to use the full potential and flexibility of the complete package.

The last option, a certified package with a smoke fan and frequency converter, allows the facility managers to use variable speed-controlled fans in the event of fires. The outcome? Maximum reliability in combination with reduced operating costs and flexibility to control the smoke control and extraction.

In a real estate market with a tendency to build higher and higher, the requirements for reliable smoke ventilation systems becomes equally higher. The need for ventilation systems that create safe escape routes, assist the fire brigade in smoke extraction and protect the building are a critical factor.

From wasting to saving energy

Using frequency converters allows you to operate the fan at a wide range of flow rates. In effect, the fans become dual-purpose fans with a VSD. They can be used for normal ventilation purposes, and they can operate as smoke extraction fans in case of fires. In the EU, the above options 1 and 2 apply to smoke fans, which are not certified together with a VSD. But when you choose a certified smoke fan and frequency drive package, you know that it complies with the rules in force.

Jos Wissink, Business Development Manager at NOVENCO Building & Industry, says: “As high-efficiency fans with VSD are now available as a certified package for smoke extraction, facility managers have the possibility for a more profitable set-up: maximum energy savings and state-of-the-art smoke ventilation system all in one solution”.

Going green: additional cost-saving benefits

Since the power consumption is reduced with high-efficiency smoke fans, the necessary power supply and related costs to the power supply systems can be scaled down. In addition to the energy savings, you can reach further initial cost savings through smaller power cables and a reduction of the normal and emergency power supply system costs.

Even though the installation costs of a certified package with a smoke fan and frequency converter may be higher than other alternatives, the initial total investment costs and running costs are reduced to a degree that makes the investment highly attractive. The key is to look at the total lifetime costs – and not just one element in the package.

For example, a comparison of the same system shows the differences between industry standard solutions such as the NOVENCO NovAx range of axial smoke fans and the high-efficiency range of ZerAx smoke fans. With all selection variables set to the same setting, the electrical power input requirement for the NovAx ACN 1250 F300 is 65kW versus 56kW for the ZerAx AZN 1250. The difference in power consumption is almost 14 percent which will lead to considerably lower running costs. Furthermore, power supply equipment, including UPS systems, can be dimensioned 14 percent smaller, resulting in lower initial investment costs. And with a lower sound level, the ZerAx is the obvious choice.

High efficiency and low sound levels

One of the most interesting features when choosing a certified fan and VSD package is the efficiency level. It impacts the operating costs, reduces CO2 emissions and benefits the environment. NOVENCO’s ZerAx axial flow fan reaches efficiency levels up to 92 percent and an impressive 98 percent recyclability rate after more than 20 years in operation. This makes it the most efficient and probably also the most sustainable dual-purpose fan on the market today.

At the same time, as a result of the optimal aerodynamic design, the fan has extremely low sound levels. For normal ventilation modes, you require less silencing, and the attenuators can be smaller – or even omitted. This results in lower system resistance and, therefore, even less power is needed. Consequently, both installation costs and running costs are reduced.

When safety is the first priority

Some might say that the cost reductions are an added bonus. The main advantage is that you can count on the highly reliable ZerAx smoke fans with Danfoss VLT frequency converters to do the job, they are designed to do: operate as certified emergency systems that must not fail.

If your emergency system fails, human lives are at risk and knowing that the smoke fan is tested and certified for operation at hot smoke temperatures gives peace of mind. With the ZerAx and Danfoss VLT package, you create safe escape routes for the occupants, assist the fire brigade in firefighting and protect the property. Reliability is at the core and choosing a certified solution guarantees that the fans can endure long-duration smoke and heat exhaust situations.

When safety is your first priority, a certified smoke fan and VSD package is the natural choice simply because it is reliable in every aspect.

About NOVENCO

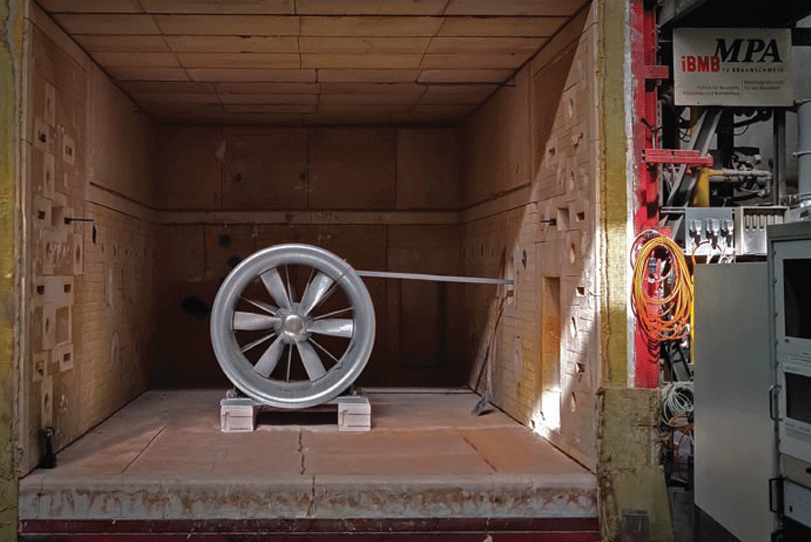

NOVENCO designs, develops and manufactures ventilation products and systems used in a range of applications all around the world. NOVENCO is a certified smoke control company and a member of the Smoke Control Association (SCA). The complete range of NOVENCO ZerAx HT fans has been tested and certified as smoke fans in combination with Danfoss VLT drives according to EN 12101-3:2015 by the German MPA in Braunschweig.

With the update of the European Standard for powered smoke and heat control fans in 2015, options were provided to use smoke exhaust fans with variable speed drives (VSD) in case of a fire. This opened up new possibilities for safer, greener and more economical solutions.

Author:

Jos Wissink, Business Development Manager at NOVENCO Building & Industry

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.