Raman Singh, a Lead System Engineer in HVAC consultant, delves into the evolving scenario of low GWP refrigerants transition, regulatory impacts, safety considerations in the refrigeration and air conditioning industry and the challenges of implementing ammonia in the F&B sector.

How do you view the utilisation of low GWP refrigerants in evolving situations?

Low GWP (Global Warming Potential) refrigerants are the hottest topic currently in the global refrigeration and air conditioning industry. Developed nations such as Europe and the United States are actively addressing environmental concerns by advocating for HFO (Hydrofluoroolefin) and natural-based refrigerants. Extensive research has been conducted in these regions. In contrast, countries like India, South East Asia, Kuwait, and Oman, falling into the Group 2 category, show a more lenient approach to enforcing low GWP refrigerants. The emphasis, however, is more on discussions, papers, seminars, and conferences than on practical implementation at the grassroots level.

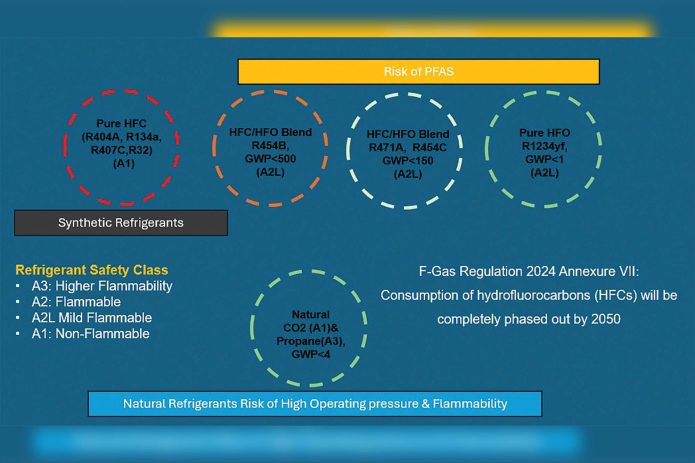

Refrigerants like R134a, R410A, and R404A remain widely accepted in the Indian market due to significant cost differences compared to HFOs. In contrast, developed nations have phased out these refrigerants entirely, transitioning to low GWP alternatives such as R1234yf, R1234ze, R448A, R452B, and R454B. An overlooked aspect is understanding the limitations and challenges associated with implementing low GWP refrigerants in HVAC (Heating, Ventilation, and Air Conditioning) and refrigeration equipment.

What role do natural refrigeration technologies play in CSR initiatives?

Natural refrigeration technologies have merits and can be utilised in corporate social responsibility (CSR) initiatives. However, they may not be the optimal primary source for refrigeration systems. At present, refrigerant-based systems prove to be efficient and deliver the desired temperature and humidity levels while occupying minimal space and providing the necessary capacity tailored to customer requirements.

Please elaborate on regulatory standards and global initiatives to promote the adoption of GWP refrigerants.

The European Union has recently entered into the latest agreements, such as EU 573/2024, which outline a comprehensive plan for phasing out hydrofluorocarbons (HFCs) consumption by 2050. Based on production rights allocated by the Commission, the production of HFCs is set to undergo a phasedown to a minimum of 15% starting in 2036. The provisional agreement specifies a complete ban on small (<12kW) monobloc heat pumps and air conditioning systems containing F-gases with a GWP of at least 150, beginning in 2027 and a full phase-out by 2032.

In Europe, there is a clear emphasis on natural refrigerants like propane and carbon dioxide as the only sustainable solutions, boasting a global warming potential of 4 and 1, respectively. Notably, the Environmental Protection Agency in the United States issued a Final Rule on September 23, 2021, aiming to reduce hydrofluorocarbon emissions by 85% over 15 years. This global trend highlights a collective commitment by nations to explore low GWP alternatives and mitigate greenhouse gas emissions. In this context, India’s Cooling Action Plan (ICAP) aligns with phasing out HFCs, although there is a call for an expedited approach similar to European regulations.

What information should compressor manufacturers include in their bulletins on retrofitting refrigeration systems with low GWP refrigerants?

There is no need for low GWP refrigerants in refrigerators since they already utilise a natural refrigerant – isobutane – effectively and safely. However, retrofitting offers substantial opportunities to implement low GWP refrigerants into existing systems. Retrofitting demands a comprehensive system understanding to avoid potential dangers and life-threatening situations. Compressor manufacturers need to provide accurate bulletins on retrofitting, encompassing aspects such as compatibility with compressor oils, filter driers, and the proper setting of expansion valves (TXV) and electronic expansion valves (EEV). These parameters play a pivotal role in addressing concerns during retrofit processes.

In what ways do international regulations influence the advancement of refrigerants characterised by lower GWPs?

The Kigali Amendment was implemented in 2016 as an extension to the 1987 Montreal Protocol. It aims at an 80% reduction in the production and consumption of hydrofluorocarbons (HFCs). This reduction is expected to prevent an additional 0.4 degrees Celsius of warming by the year 2100. These amendments are commendable as they compel equipment manufacturers to shift their focus towards developing low Global Warming Potential (GWP) refrigerants. However, it is essential to note that even low GWP refrigerants come with loads of indirect emissions, including designing and developing new components like compressors, compressor oils, and switch gears to support these refrigerants. Using low GWP refrigerants is one of many solutions to the problem. Still, the regulating bodies need to focus on the recyclability and recoverability of materials like copper, brass, Al, and zinc to establish a balance between direct & indirect emissions.

What safety measures should regulatory bodies ensure in their publications to safely utilise ammonia?

Ammonia is a highly efficient and cost-effective heat transfer fluid compared to HFCs or HFOs. Currently, several regulations are in place to ensure safe operations. Regulatory bodies such as the AAR should publish guidelines to ensure the safety of operations. These should cover aspects like ammonia leak detectors, cascade refrigeration systems, guidelines for welding and brazing, certification programs for training technicians and customers, and implementing guidelines to prevent corrosion. The government also must ensure that proper safety protocols are in place and addressed to uphold the safety standards of ammonia usage.

What are the probable challenges while implementing ammonia refrigeration systems in the F&B sector?

Ammonia in the food and beverage sector poses a potential risk due to its toxicity, especially in environments frequented by individuals of all age groups. To ensure safe operations, it is advisable to exclude ammonia from refrigeration systems in supermarkets, modular cold rooms, deep freezers, and bottle coolers. I believe that ammonia refrigeration systems are best suited for implementation in locations with limited access, minimising the potential exposure to a smaller and controlled number of individuals.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.